As soon as winter arrives, road cracks and cracked walls are found to be difficult to construct, simply because the water contained in the soil, concrete, mortar, etc. is frozen when the average outdoor temperature is stable below 5 ° C for 5 consecutive days Crack, to the construction of many difficulties. However, adding polypropylene engineering fibers into concrete can greatly improve the performance of concrete and effectively improve the disadvantages of concrete itself. Shandong Huimin Zhiwei Chemical Fiber Products, Polypropylene Engineering Fiber!

Polypropylene Engineered Fibers (Mesh) Used in cementitious concrete reinforced fiber products

TY-D modified polypropylene for mortar and concrete Engineering fiber is an independent research and development product of Changzhou Tianyi Engineering Fiber Co., Ltd., which is added to mortar or concrete to restrain the plastic shrinkage cracks of cement mortar and concrete before curing. Increase the toughness of cement mortar and concrete, thereby enhancing the inherent quality of cement mortar and concrete, reduce maintenance costs and prolong the service life of the project.

Technical solutions:

The technology through a special anti-static and anti-UV treatment, the fiber dispersed in concrete uniform, long-term play its effectiveness; the fiber "Y" cross-section increased fiber surface area; fiber grafting and physical modification by chemical treatment, the surface roughness Porous, greatly improving the fiber and cement-based aggregate binding. Monofilament polypropylene fibers are added to the concrete base and mixed quickly and easily with the mortar concrete. As the fiber is fine, the specific surface area is large, there are nearly 20 fibers per 1cm3 of concrete, so it can form a kind of random orientation support system inside the concrete, which can effectively control the early plastic shrinkage and shrinkage of concrete and cement mortar. The generation and development of non-structural fractures effectively obstruct the segregation of aggregates and hinder the formation of subsidence cracks. Greatly improve the impermeability of concrete, impact resistance, increase the toughness and wear resistance of concrete, so that the life of the building greatly extended.

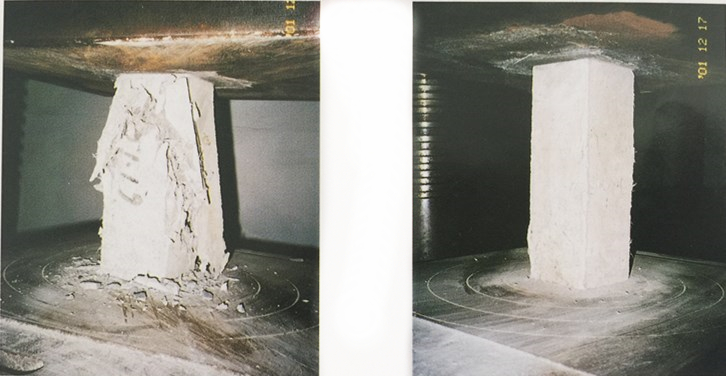

without fiber-reinforced concrete Add fiber-reinforced concrete

The use of polypropylene engineering fiber products can significantly improve the fiber and mortar, concrete bonding performance, improve the early mortar, concrete anti-cracking, effectively prevent the occurrence of mortar and concrete cracks and development to ensure uniform bleeding, to prevent tube segregation, Hinder the formation of subsidence cracks. Experiments show that the volume content of 0.1% of the fibers, mortar cracking capacity increased by 70%, but also significantly improve the impermeability of up to 60% -70% (compared to ordinary cement).

The use of polypropylene engineering fiber products can significantly improve the impact resistance of concrete and wear resistance. Polypropylene fibers have low stiffness and poor ability to transfer charge and cut ends, but they can absorb impact energy, reduce cracks effectively, enhance continuity of dielectric material and reduce local stress caused by shock waves being blocked. Therefore, polypropylene fiber can greatly enhance concrete Impact resistance and toughness.

The use of polypropylene engineering fibers can improve the frost resistance of concrete. Addition of polypropylene fiber to concrete can relieve the effect of internal stress caused by temperature changes and prevent the expansion of temperature cracks. Meanwhile, the improvement of frost resistance of concrete also contributes to the enhancement of frost resistance. Practice and research have shown that the addition of polypropylene fiber in concrete can be used as an effective means of temperature compensation for concrete anti-cracking.

The use of polypropylene engineering fibers can improve the toughness of mortar and concrete, significantly improve the product edges and surface integrity, which is conducive to products within the steel is not subject to corrosion.

The PP engineering fiber chemical stability, safety and non-toxic, acid and alkali, anti-magnetic anti-rust, and cement with strong, do not change the original mix, simple construction without special requirements. Economical and reliable, easy construction, can not change the original ratio, no special requirements, and now in many large projects through the use of, has made the user's one to praise. The large-scale use of tennis courts at the Nanjing Olympic Sports Center has achieved remarkable results. The use of large-scale naval naval port in Zhuhai, Guangdong Province, and the use of many projects in Changzhou, such as the People's Defense of Huaide Square, achieved good results.

Polypropylene engineering fiber Usage:

1. Spike ratio: per cubic meter of concrete, mortar polypropylene mesh fibers in the general volume of 0.1%, weight of 0.9kg, the greater the amount of doping, the better the anti-cracking effect, but the general dosage Not more than 0.15%.

2. Fiber Length: Polypropylene mesh fiber is recommended for concrete to a length of 19mm and for cement mortar to be 10-15mm. Generally, when the fiber length is less than 20 mm, the longer the fiber length, the better the plastic anti-cracking effect. The longer the fiber, the better the flexural toughness of the concrete produced.

3. Mixing Process: Mixer can be added before, after or simultaneously with other mixes.

4. Stirring time: Under normal circumstances, the same stirring time or slightly longer than the conventional mixing time extension of 3-4 minutes, extended mixing will not affect the fiber distribution and fiber strength, but will not cause clumps.

5. Blender selection: priority biaxial horizontal forced mixer, but also can be used self-rolling mixer, or pulp plate mixer.

Polypropylene engineering fibers to make the world no longer crack the road! Improve the life of the road, increase the life of the wall, no longer spend more money wasted.

Founded in 2003, after years of arduous pioneering, the company has developed into a specialized large-scale polypropylene fiber company that integrates production and sales. The main products are: polypropylene fiber, polypropylene fiber, polypropylene medium strength fiber, polypropylene high strength fiber, High-strength polypropylene filament, polypropylene rope, safety net, polypropylene engineering fiber, polypropylene mesh fiber, polyester fiber.